Issue Material

Issue allows you to track, report, and utilize material(s), track which location they were issued from, track their velocity, ABC ranking, and many other criteria all helping to maintain the accuracy and accountability of inventory.

|

|

TIP: For a quick start guide on this subject, see Issue Material.

TIP: For a quick start guide on this subject, see Issue Material.

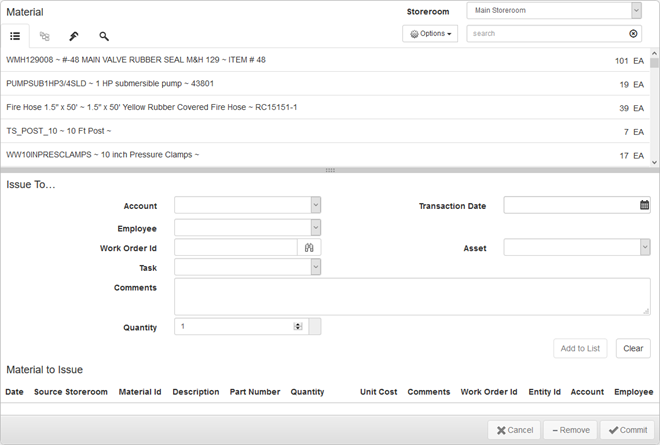

- Click Issue on the Storeroom toolbar.

- Select a Storeroom from the drop-down list. This changes the list of materials. You may only select materials from one storeroom at a time.

- Select materials from the list. See Material Panel for information on using the search tabs to find materials.

TIP: To select multiple materials use <Shift + click> or <Ctrl + click>.

TIP: To select multiple materials use <Shift + click> or <Ctrl + click>.

NOTE: Assembly materials in the material list include an Add Parts check box. Selecting this check box, before adding the assembly to the Issue To list, enables users to edit the materials that make up the assembly once they have been added to the list.

NOTE: Assembly materials in the material list include an Add Parts check box. Selecting this check box, before adding the assembly to the Issue To list, enables users to edit the materials that make up the assembly once they have been added to the list.

- Enter the information in the Issue To panel below the material list to issue the material.

For an explanation of the fields found on the Issue To panel, see Issue Transaction Fields.

NOTE: To issue material to an account, employee, or a specific work order, see Assign Material to an Account, Assign Material to an Employee, and Assign Material to a Work Order.

NOTE: To issue material to an account, employee, or a specific work order, see Assign Material to an Account, Assign Material to an Employee, and Assign Material to a Work Order.

- Click Add to List to add the material to this issue transaction.

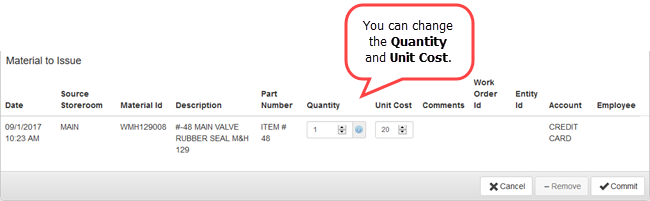

You can adjust the Quantity and the Unit Cost before committing the material, if desired.

NOTE: To view the unit of measure of the material, hover the mouse over the icon next to the Quantity.

NOTE: To view the unit of measure of the material, hover the mouse over the icon next to the Quantity.

- If you would like to add other materials to this issue transaction, click Clear to clear the fields and add another material to the list.

- To remove one of the records from the list, select the record and click Remove.

- Click Commit to process all the issues listed. Clicking Commit issues the material from the storeroom selected, and assigns them to the selected account, employee, and/or work order.

NOTE: When assembly materials have been issued to a work order, click the Add assembly parts icon in ELM to individually view and add the component parts instead of the assembly item to the work order. See

NOTE: When assembly materials have been issued to a work order, click the Add assembly parts icon in ELM to individually view and add the component parts instead of the assembly item to the work order. See

Documentation Feedback Form

Please give us feedback about this Cityworks guide.

If you have a feature enhancement request, please see the Ideas page on MyCityworks.

Last updated 1/3/2020.

Copyright© 2014–2019 by Azteca Systems, LLC. All rights reserved.